Leistungen

Auf allen Stufen des Prozesses stehen wir Ihnen als kompetenter Ansprechpartner zur Seite – von der ersten Beratung, über die Angebotsausarbeitung, bis hin zur operativen Umsetzung sind wir in allen Fragen Ihr Ansprechpartner.

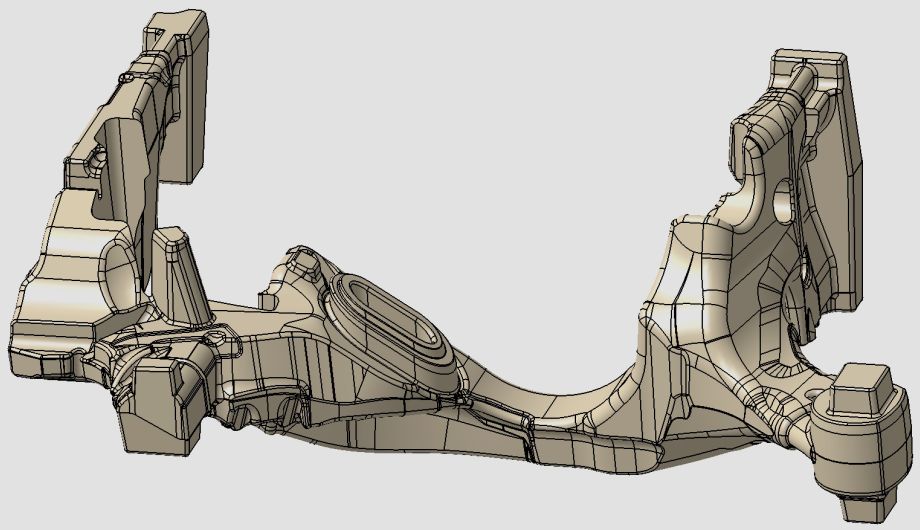

Beratung und Konstruktion

Unser Team im Projektmanagement unterstützt Sie dabei von der Produktidee bis zur Serie in vielfältiger Weise. Wir beraten Sie bei der Werkstoffauswahl, der kunststoffgerechten Bauteilekonstruktion und unterstützen Sie bei der Suche nach innovativen Montagelösungen sowie der wirtschaftlichen Optimierung.

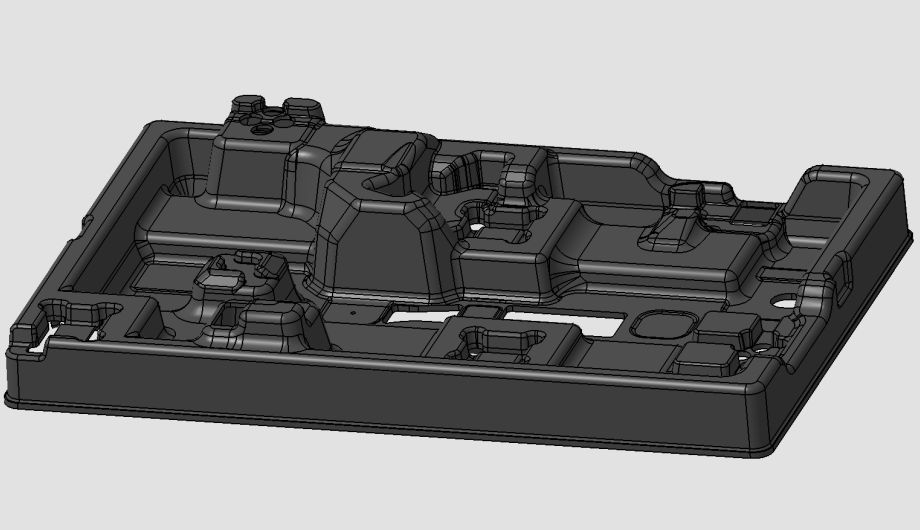

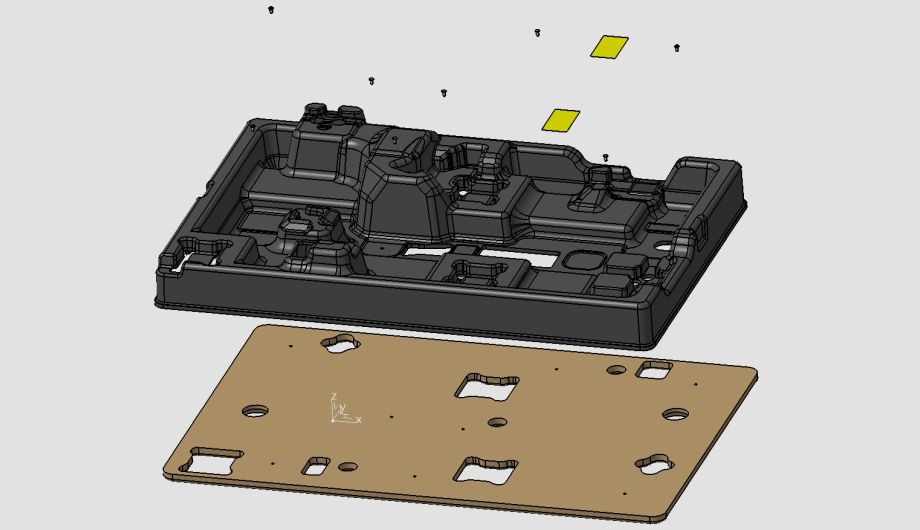

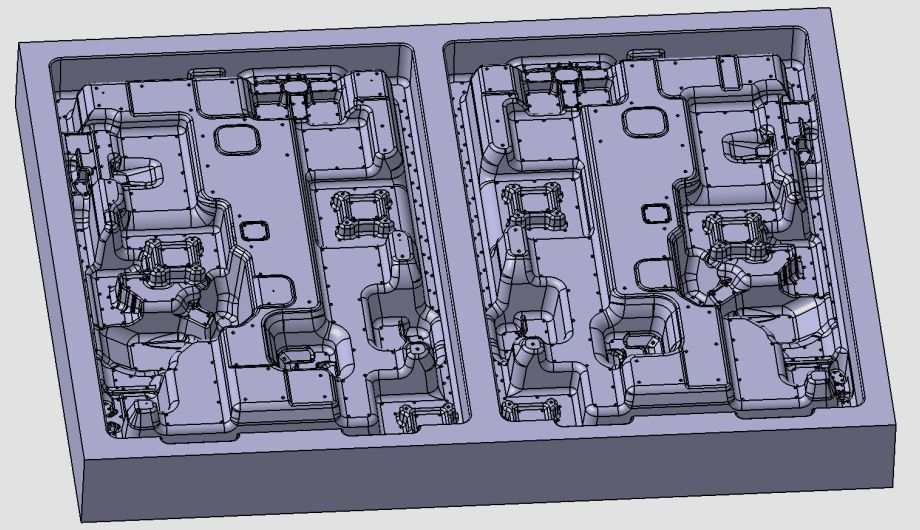

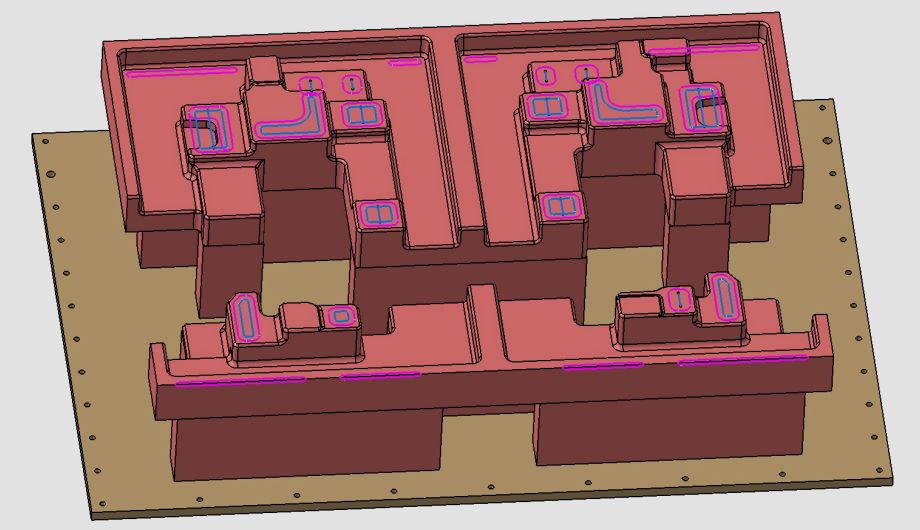

Formenbau

Eine Kernkompetenz von REBOPLASTIC ist seit jeher die Entwicklung und Produktion aller benötigten Betriebsmittel. Die Herstellung der Betriebsmittel setzen wir gemeinsam mit unseren langjährigen Partnern aus dem Werkzeugbau um. Ob komplexe Tiefziehwerkzeuge, Fräsaufnahmen oder Montagegeräte: Unsere Abteilungen Technik und Werkzeugvorbereitung sowie externe Partner tragen maßgeblich zum Unternehmenserfolg bei.

Thermoformung

Unsere zentrale Aufgabe ist die Herstellung von technisch anspruchsvollen thermoplastischen Kunststoffteilen. Prozessabläufe, z.T. unabhängig von menschlichen Einflussfaktoren, genügen höchsten Qualitätsansprüchen. Eine zentrale Materialtrocknungs- und Förderanlage und moderne, extra große Vakuumtiefziehmaschinen mit automatisierten Handlingsystemen zählen zu den Highlights unserer Fertigung.

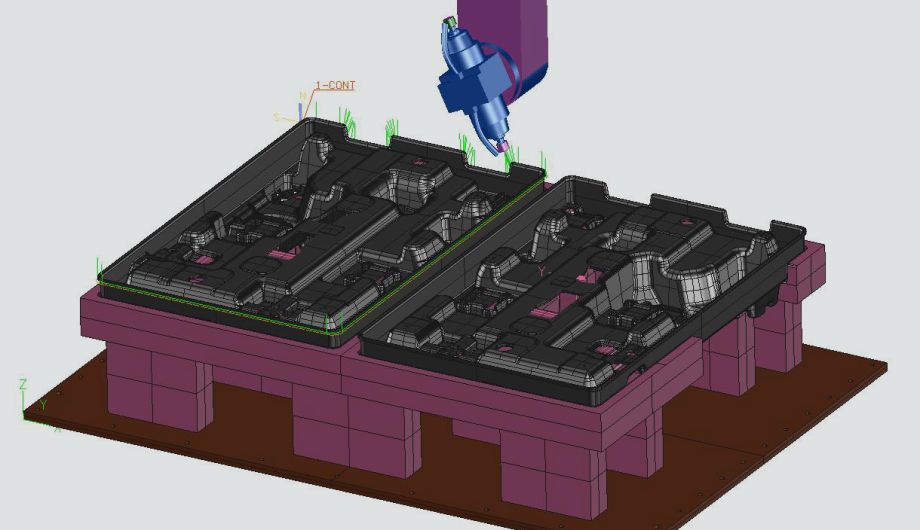

CNC-Fräsen

Eine Vielzahl unserer Produkte haben hohe Anforderungen an die Genauigkeit des Beschnitts. Die Bearbeitung dieser Teile erfolgt auf speziellen 5-Achs-Fräsen, die sich durch eine große Wiederholgenauigkeit, hohe Verfahrensgeschwindigkeiten und Spindeldrehzahlen auszeichnen.

Baugruppenmontage

Unsere prozesssichere Montage ist ein qualitäts- und kostenrelevanter Arbeitsschritt in der Fertigungskette von Baugruppen. Unser Leistungsspektrum umfasst neben der klassischen Montage auch das Schweißen, Bedrucken, Kleben, Konditionieren, Prüfen und Verpacken von Bauteilen.

Logistik

Unser Hochregallager bietet Platz für über 3.000 Paletten. Rohmaterialien, Fertigwaren sowie Werkzeuge und spezielle Bearbeitungsmaschinen werden hier eingelagert.

Qualitätsmanagement

In Qualitätsfragen kennen wir keine Kompromisse. Unser Management-System gewährleistet kundenorientierte Qualitätsanforderungen. Kein Produkt verlässt ungeprüft unser Haus. Die Kundenbetreuung sorgt für eine individuelle Vorserienplanung – von der Anfrage über Prozessentwicklung und FMEA bis zur Serienfreigabe.

REBOPLASTIC ist zertifiziert nach DIN EN ISO 9001: 2008.

Vereinbaren Sie einen Termin für ein unverbindliches, kostenfreies Kennenlernen unter 05733 9101-0.

Dieter Morthorst, Geschäftsführer